Join us in achieving the highest levels of production efficiency and increasing the quality of your products!

CASEmes is a manufacturing execution system that allows you to control, document, and evaluate your production processes. The quality of processes and products is made measurable through key performance indicators (KPIs). This can uncover optimization potentials in your manufacturing processes. The basis for this is the connection of machines to CASEmes to collect and analyze data.

Functionality and Technology:

CASEmes consists of several services that are responsible for data acquisition and processing. The GUI, implemented as a Web application, is used to configure the production processes and visualize the data. Users can get a quick overview of the most important production parameters, such as production quantities, OEE, etc., through various dashboards. CASEmes is modularly structured and can be customized to meet specific needs.

Example Features:

Example Features:

Benchmarking:

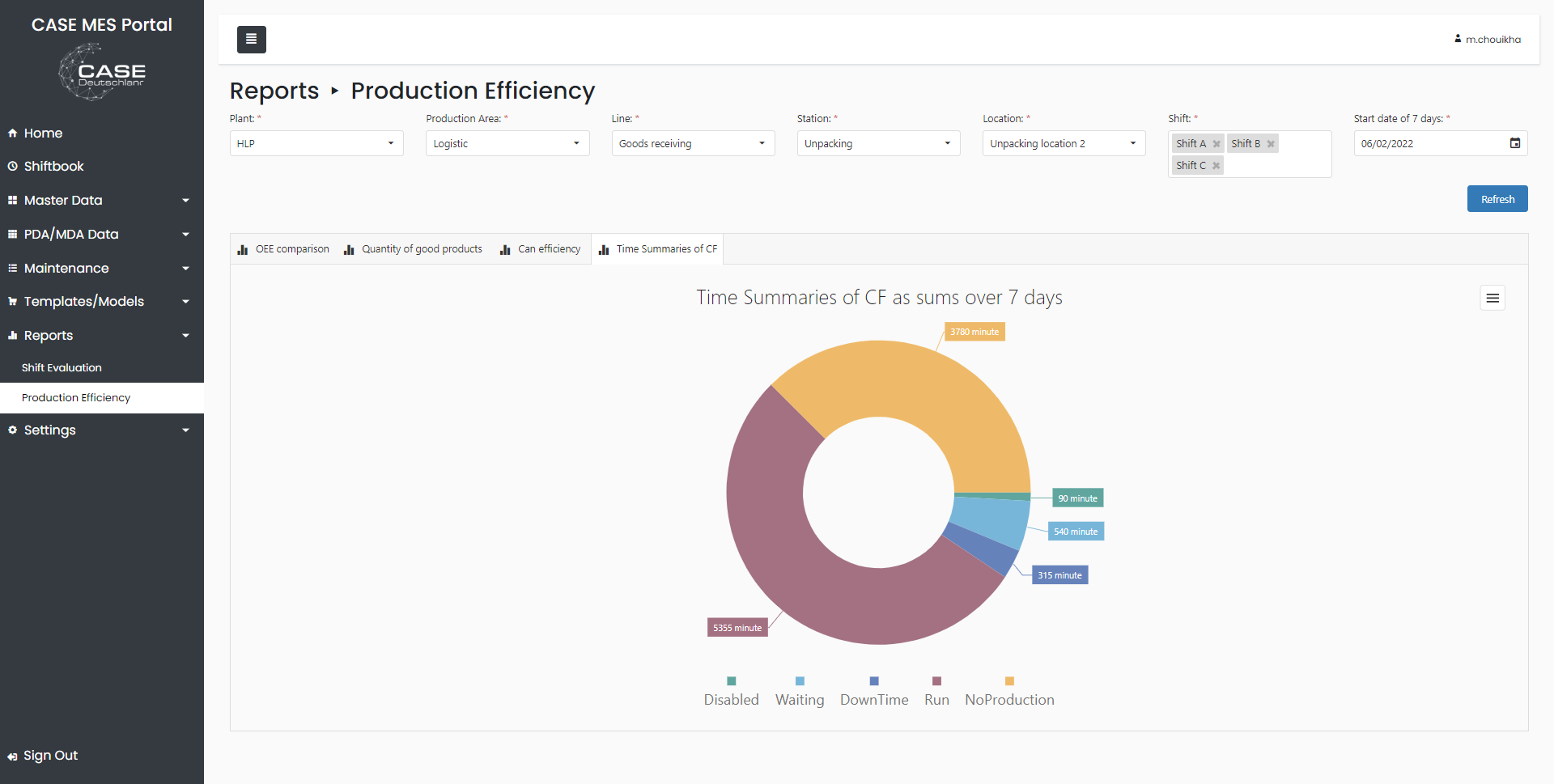

CASEmes can provide a range of tools for performance comparison, including real-time dashboards, reports, and alerts that highlight areas where performance is below target or benchmark values.

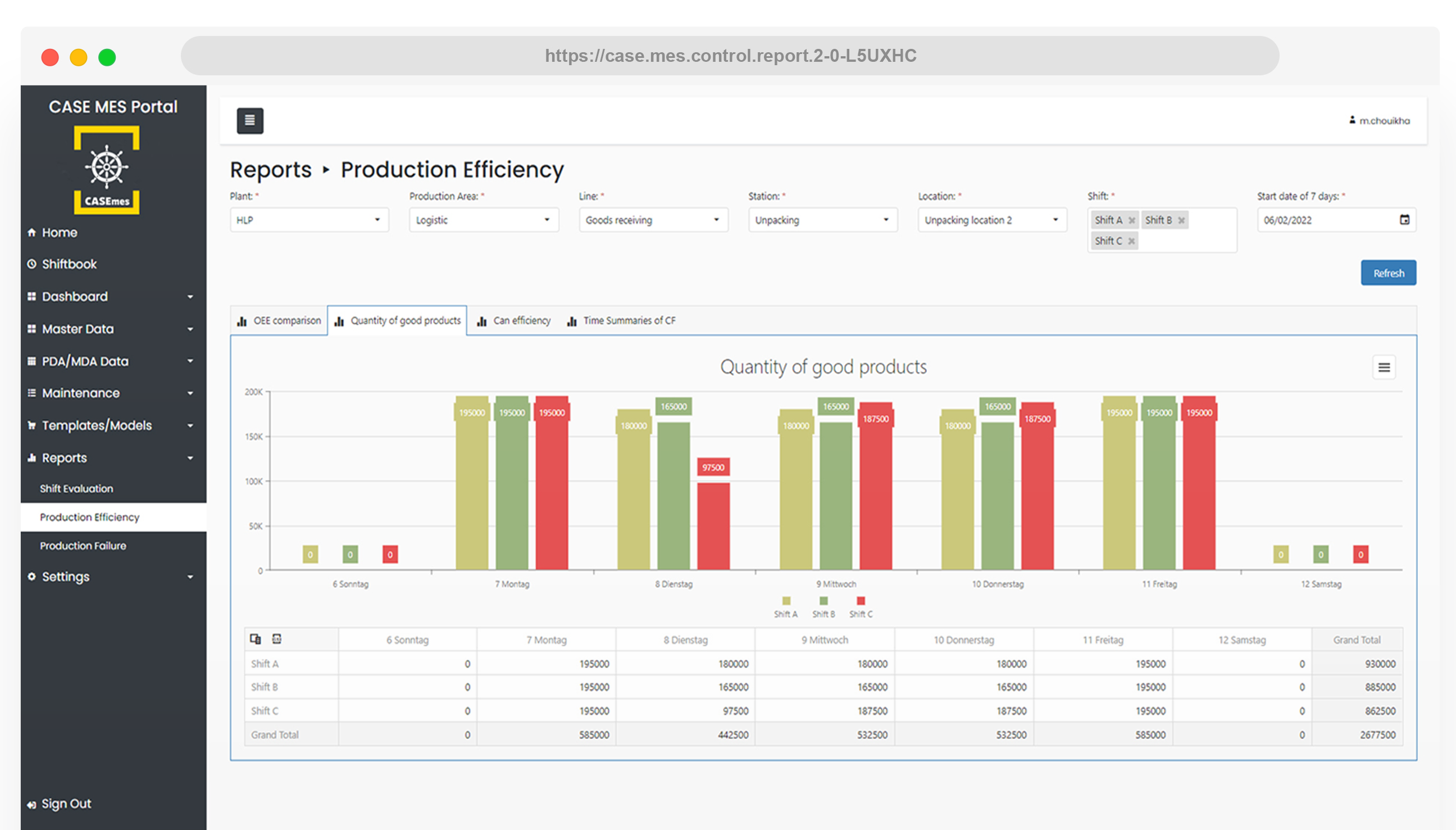

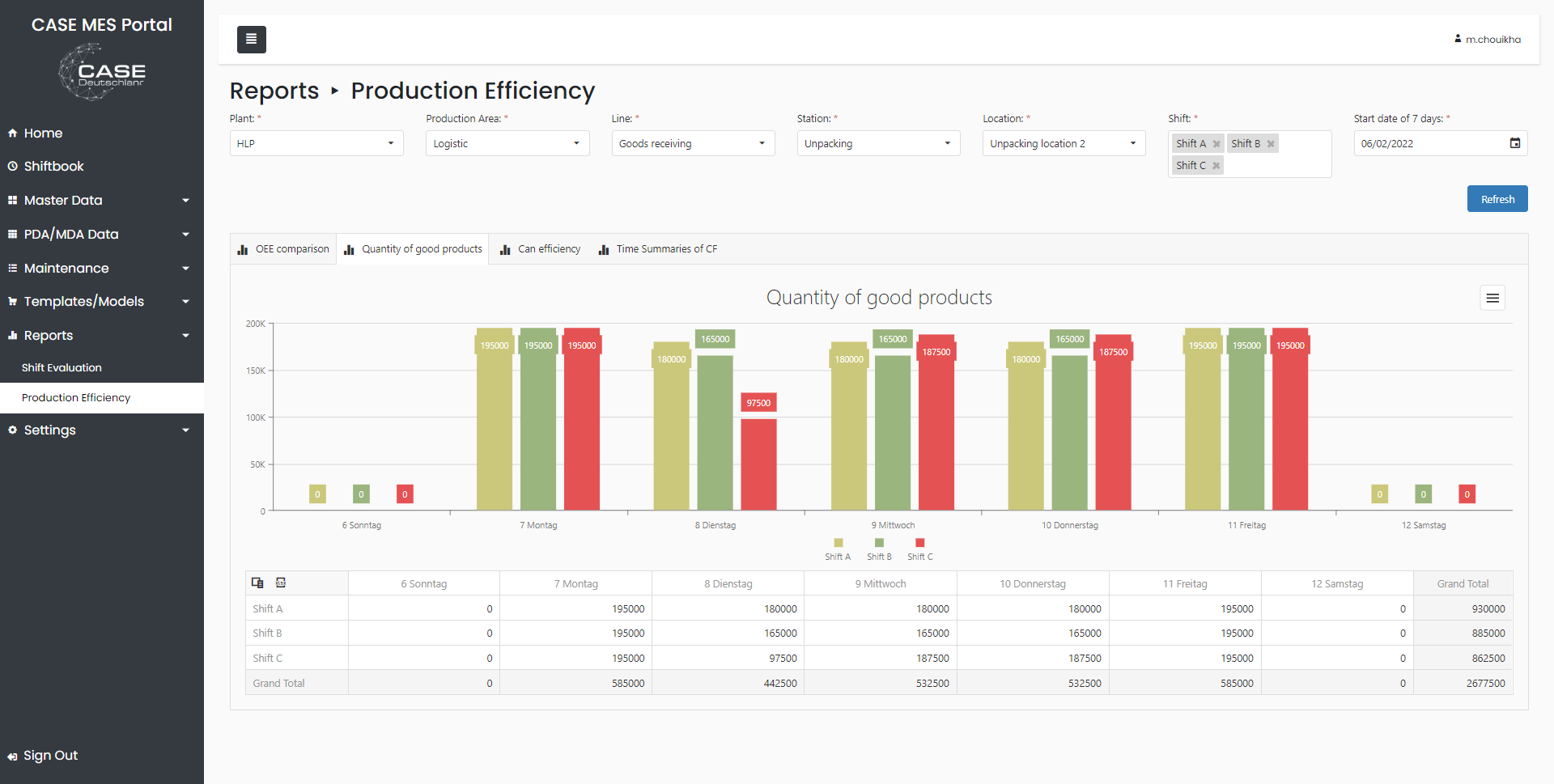

Manufacturing (KPI’s):

The weekly overview provided by CASEmes is a summary of the most important key performance indicators (KPIs) that help managers and executives evaluate production performance and identify trends.

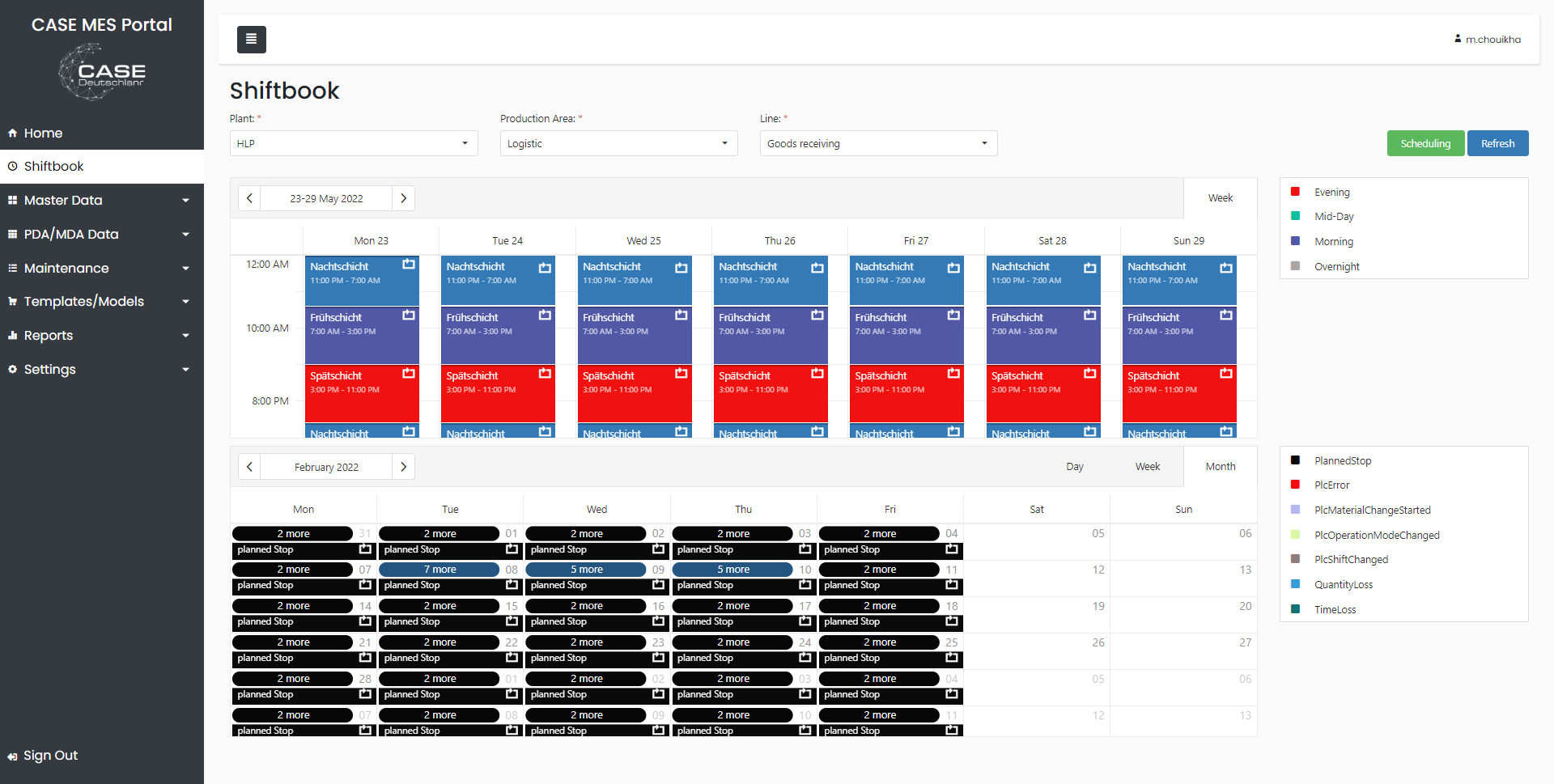

Shift Book:

CASEmes offers an efficient and effective way to track production activities and events, allowing manufacturers to optimize production processes, reduce waste, and increase overall efficiency.